Drilling for Medical Success

Warning: video contains graphic images of surgical procedures

Surgical drills are vital where bone must be bored, screws set, limbs and lives saved. They are high-tech, sleekly robust, able to repeatedly endure autoclave sterilization. At about $30,000 per unit, they’re also expensive.

In the cash-strapped developing world, orthopaedic surgeons rely on hand-powered drills. Imprecise and slow but their simplicity makes for easier sterilization. Commercial-grade power drills are the better option but their internals don’t tolerate autoclaves and their casings are open to splatter and fluid contamination.

UBC Engineering students have a better solution: Take what’s available and make it better and far more useful.

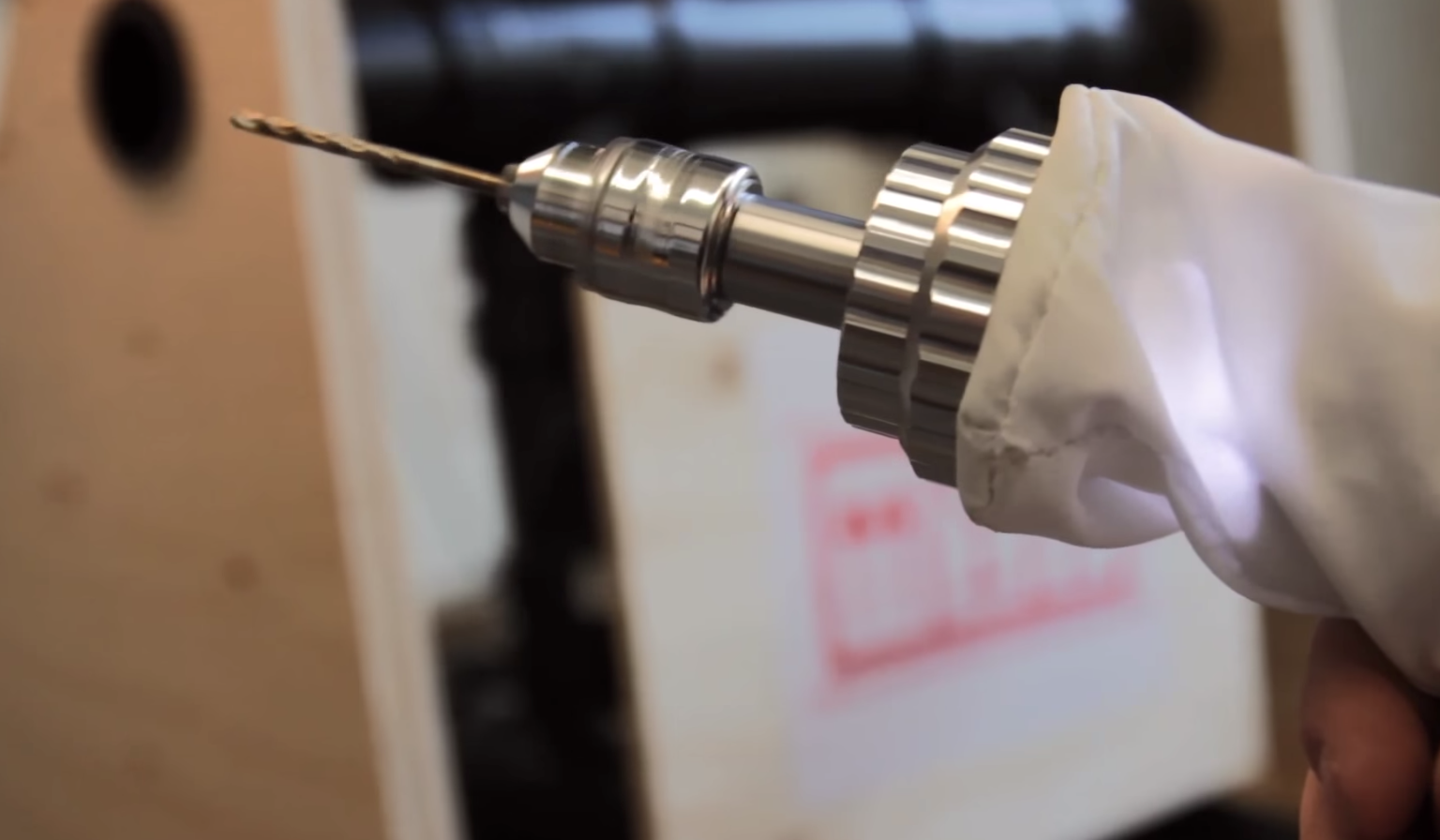

As members of Engineers in Scrubs project, which brings surgeons and engineers together to identify and solve problems in hospitals, the UBC team partnered with the Uganda Sustainable Trauma Orthopaedic Program and at the request of surgeons from Mulago Hospital in Kampala, Uganda, designed a surgical-quality cover that can be fitted over a commercial-grade power tool, something that can be bought at any well-equipped hardware store.

Thanks to the UBC-designed cover fitted over the drill, only the steel connection chuck and the inexpensive (but effective) store-bought drill bit are exposed. At operation’s end, the cover, chuck and bits are easily removed and put into the autoclave. The power tool is re-covered, refitted, and ready to go.

The estimated cost for power drill, five covers and five chucks is $500 to $800.

With guidance and support from entrepreuneurship@UBC, the student team is developing a prototype and searching for a waterproof, tough fabric with antibacterial and antiviral properties from which to fashion the surgical-quality cover.

More surgical operations, less risk of infection and in Uganda and other low-income countries where car accidents are a major cause of life-debilitating injuries, the combination of cover and power tool could see a lot of lives put back together, straight and strong.

Read more about

Research ExcellenceRead more Research Excellence stories:

- Precious Matter

- Taking the spike out of diabetes

- The Pharma Is In

- Olympic Sized Reductions

- Solar Cells? Naturally

- Sustainable Stand, No Longer a Tall Order

- Fold, Spindle, Mutate

- Bita Imam, Student Extraordinaire

- Top Researchers Recognized: UBC’s Young Researchers Shine

- Oceans of Opportunity

- Charles Fipke: A Gem of a Friend and Philanthropist

- A Royal Welcome

- Julio Montaner: Shifting the Global Conversation on HIV/AIDS

- David Cheriton: Making Everything Compute

- Doubling Down on Gambling Research

- Julio Montaner, Olav Slaymaker, Honoured

- Jaymie Matthews Rocks On In Space

- Solar Cells? Naturally

- A Calculated Drama

- An Extrudingly Good Idea

Related Content

UBC Engineering students have a better solution: Take what’s available and make it better and far more useful.