Olympic Sized Reductions

When your circulatory and filtration systems are ailing, poisoned by waste products, doctors will use a dialysis machine to clean the blood.

When it’s an entire industrial sector–the oil and gas industries and by extension, the whole world–that’s beset with the challenges of excess carbon dioxide and wastewater, simply removing the toxic effects is impressive enough.

To actually convert the liquid waste into valuable chemicals and desalinated water, that’s akin to modern-day alchemy.

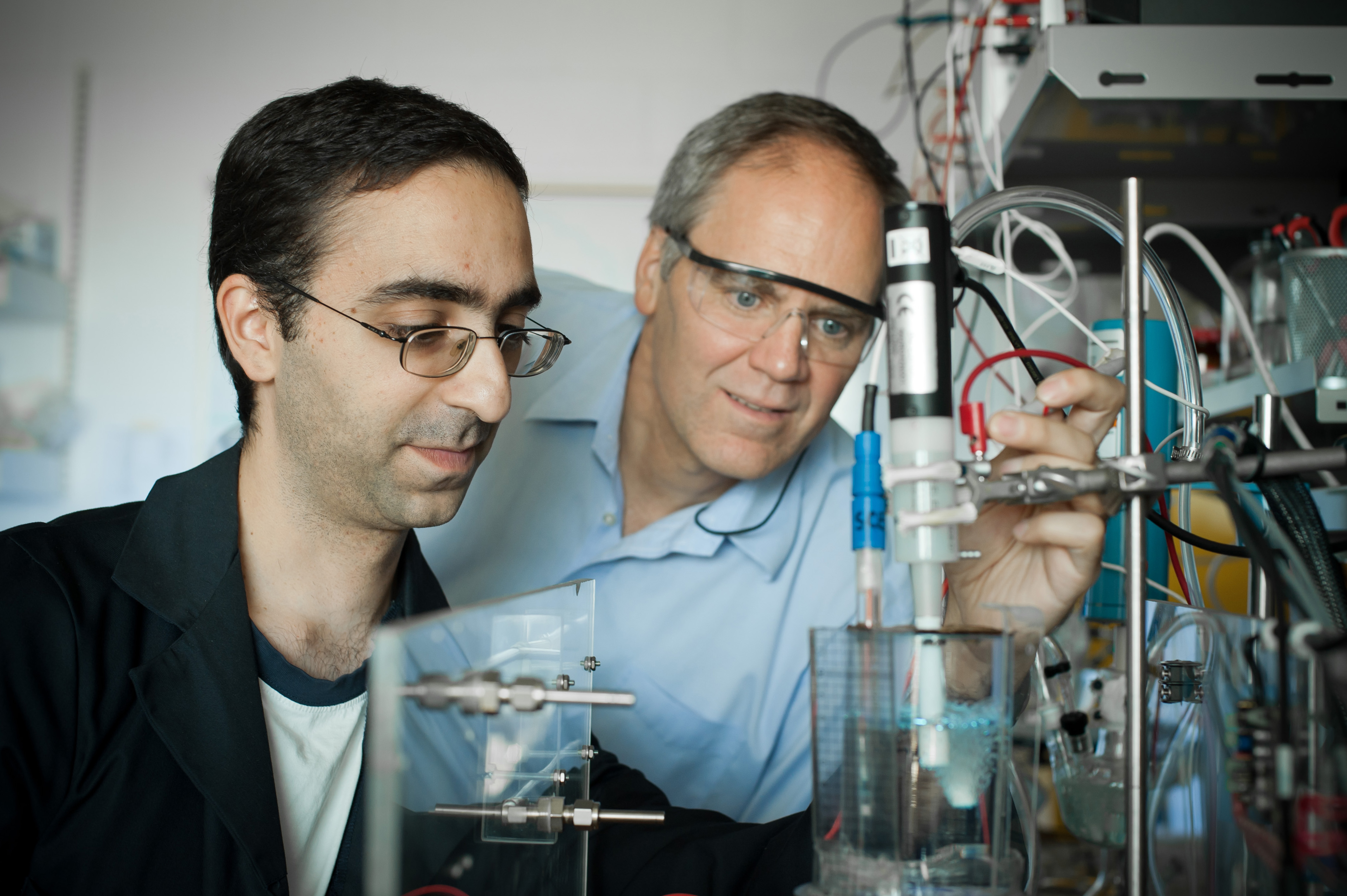

Or with UBC Professor David Wilkinson and team members Dr. Arman Bonakdarpour, Dr. Alfred Lam and PhD candidate Saad Dara in collaboration with SFU’s Professor Steven Holdcroft, it’s $500,000 from the Alberta-based Climate Change and Emissions Management Corporation to fund and assist the waste-transmutation technology toward commercialization.

Unlike standard desalination technologies (e.g. evaporation and reverse osmosis) where the only output is desalinated water, the “simple modular system” and low-energy dialysis innovation not only desalinates water via ion-selective membranes to facilitate ion movement under an electric and chemical concentration difference, it “significantly reduces the carbon footprint“ by producing valuable chemicals from waste CO2 on site.

Scaled up and applied to the Alberta oil and gas sector alone, the novel system could reduce CO2 emissions by more than one million tons per annum (the equivalent of 200,000 cars) and reduce the need for fresh water by more than two billion liters or 800 Olympic-size swimming pools.

Read more about

Research ExcellenceRead more Research Excellence stories:

- Precious Matter

- Taking the spike out of diabetes

- The Pharma Is In

- Solar Cells? Naturally

- Sustainable Stand, No Longer a Tall Order

- Fold, Spindle, Mutate

- Bita Imam, Student Extraordinaire

- Drilling for Medical Success

- Top Researchers Recognized: UBC’s Young Researchers Shine

- Oceans of Opportunity

- Charles Fipke: A Gem of a Friend and Philanthropist

- A Royal Welcome

- Julio Montaner: Shifting the Global Conversation on HIV/AIDS

- David Cheriton: Making Everything Compute

- Doubling Down on Gambling Research

- Julio Montaner, Olav Slaymaker, Honoured

- Jaymie Matthews Rocks On In Space

- Solar Cells? Naturally

- A Calculated Drama

- An Extrudingly Good Idea

Related Content

Campus

Vancouver

Comments are closed, but trackbacks and pingbacks are open.